Manufacturing facilities

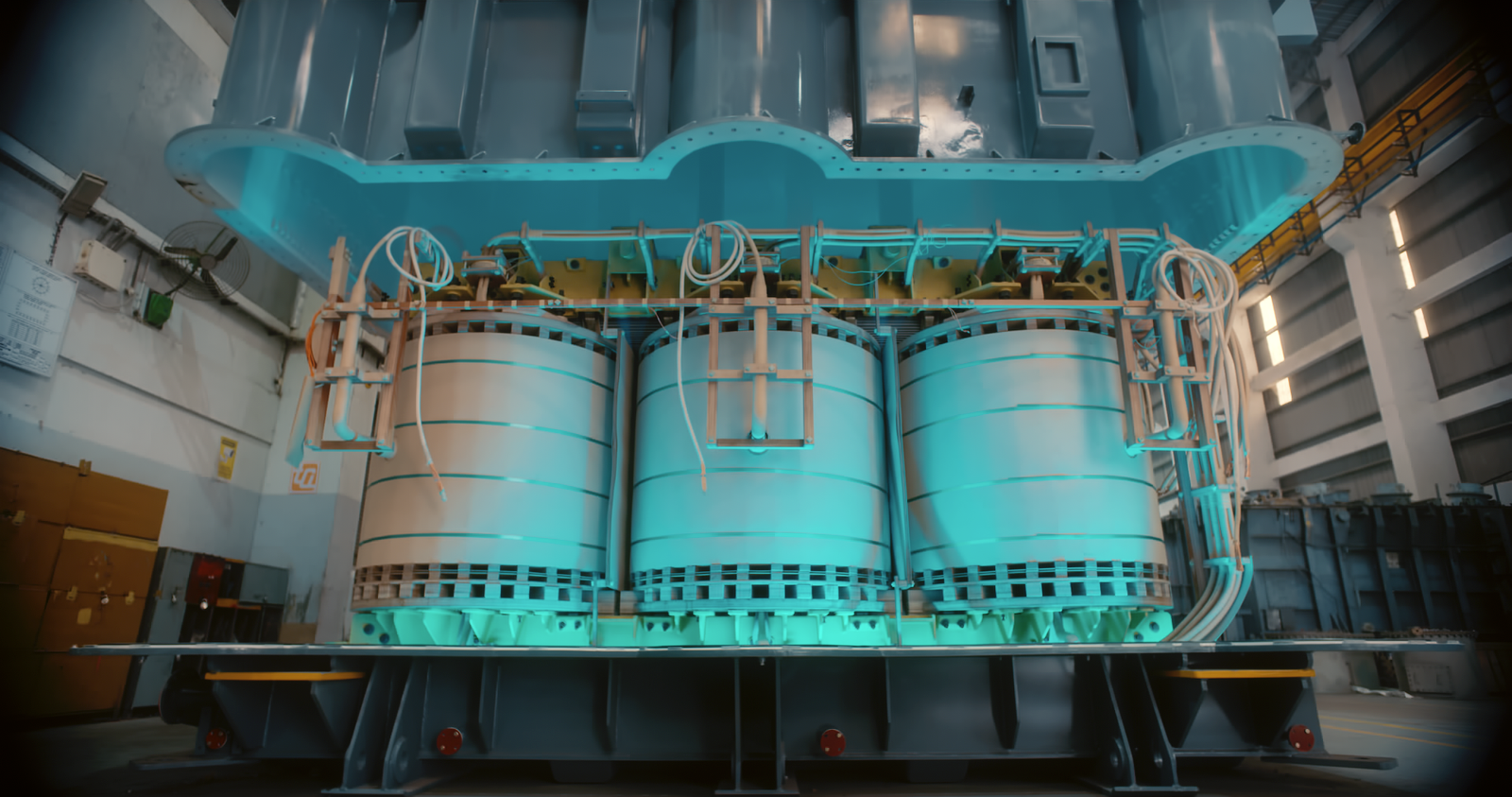

TATL’s ‘State of art’ transformer manufacturing facility spanning 12.5 acres with covered area of 23,000 sq mtrs is located in Sitarganj, Uttarakhand, Northern India. The world class facility with annual manufacturing capacity of 20,000 MVA is one of the largest EHV transformer manufacturing companies in India.

Key manufacturing facilities are-

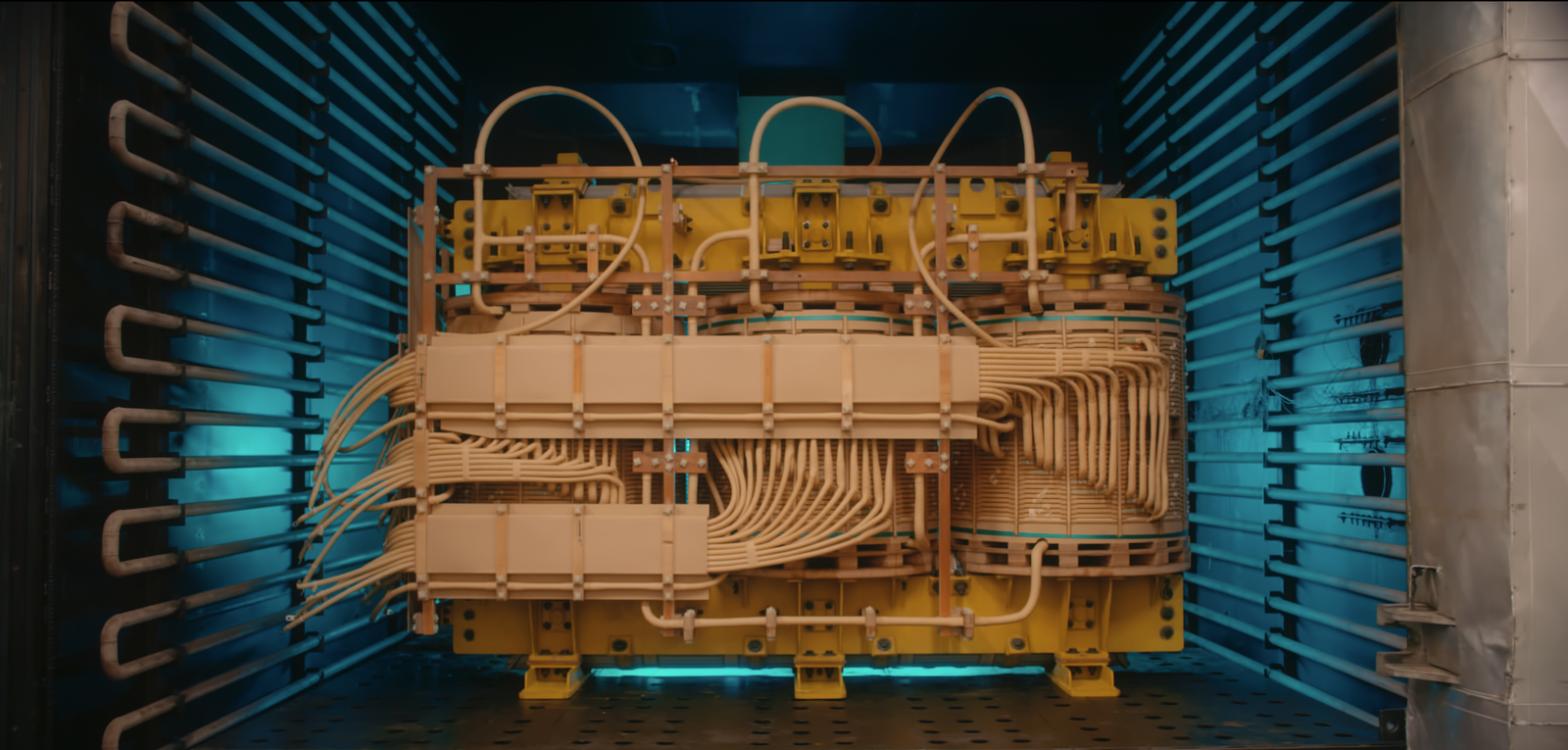

- Dust-free environment employing measures like air-conditioned winding shops and epoxy flooring in winding and assembly stations

- Well-planned raw material movement thereby reducing exposure to the environment

- Lifting Crane Capacity upto 300 MT suited for manufacturing EHV transformers upto 400 kV

- Fully functional material testing laboratory is capable of testing inward raw material in order to have a high degree of control on the raw materials being used in the transformers including captive fully functional oil testing laboratory

- High-capacity Assembly Stations for Core Erection & main tank assembly

- Isostatic pressing arrangement for coil sizing

- Vertical winding machines with enclosed Climate Controlled winding area for EHV transformers.

- Enclosed climate controlled assembly station for EHV transformers

- Vapour Phase Drying ovens for fast and optimum processing of CCAs

- Oil filling under vacuum through dedicated vacuum pumping system

- High Capacity vacuum Oil Filter machines

- Process control for limited exposure time during pre-tanking

- Captive facilities for manufacturing PICC ensuring high quality, reliability and timely delivery

- Implementation of ERP (Enterprise Resource Planning) solutions is underway for improving overall operations of the organization