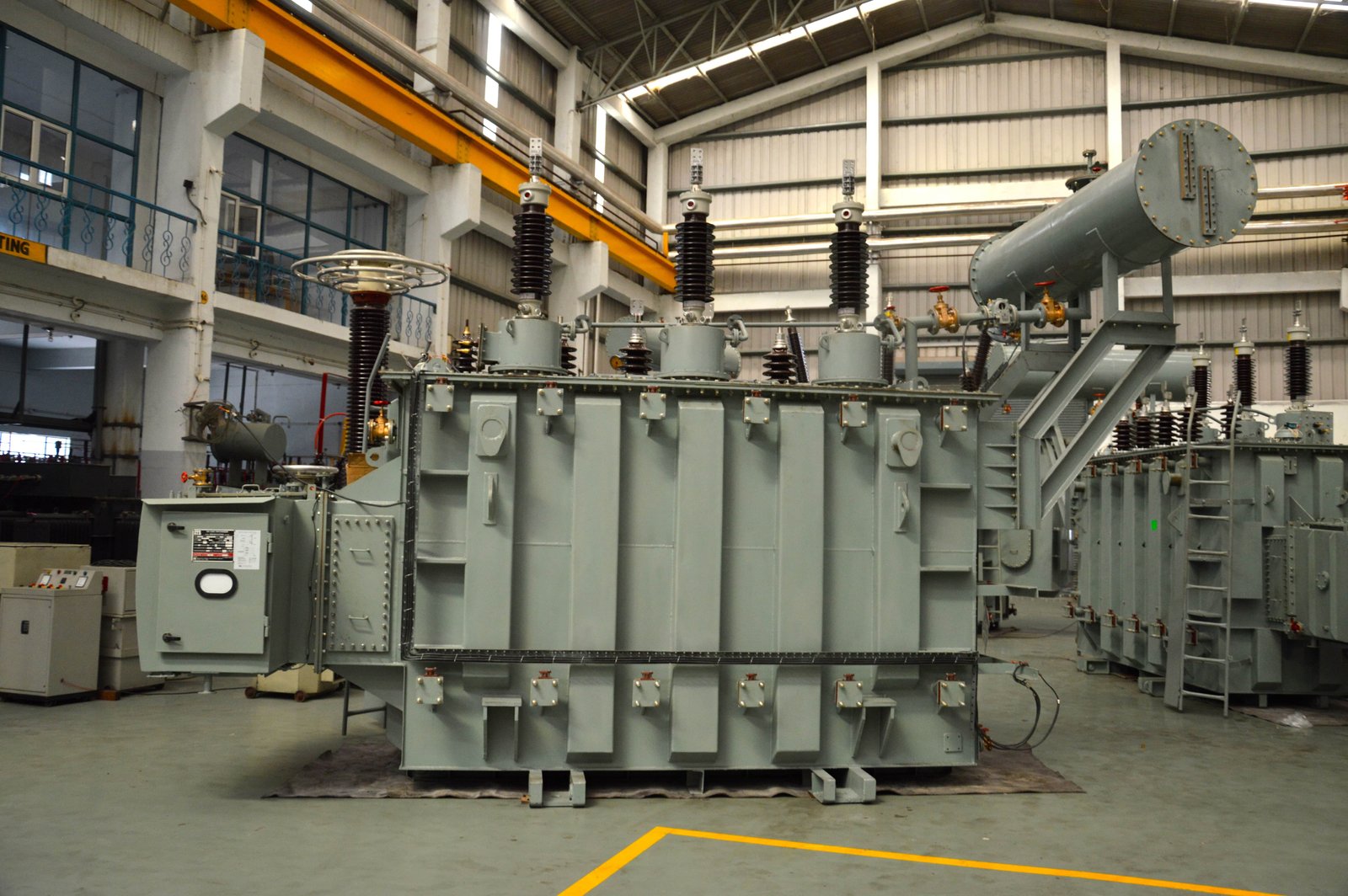

Manufacturing Facility, Sitarganj, Uttarakhand

EHV Power transformers are manufactured by TATL out of its state of the art facility at Sitarganj, Uttarakhand. Spread out over an area of 12.5 acres with total covered manufacturing area of approx. 23,000 sq mtr, this is one of India’s largest transformer manufacturing setups. Featuring heights of up to 22 mtr. in its manufacturing bays, adequate lifting capacity up to 300 MT, and all modern equipments including Vertical Winding machines, high capacity assembly stations, climate controlled winding and assembly areas and capability for conducting all routine and type tests in-house (including Impulse & Temperature Rise), TATL’s manufacturing setup is one of the most modern setups in India today.

The factory and its manufacturing processes have also been certified in compliance to ISO 45001:2018 - the Standard for Occupational Health & Safety Management System in the work place, and ISO9001:2015 – the standard for quality assurance.

Our test facilities have been assessed and accredited by the National Accreditation Board for Testing and Calibration Laboratories (NABL) for compliance with ISO/ IEC 17025:2017upto 400 KV, 500 MVA, offering further proof of robustness of the quality of transformers manufactured by us.

The Plant has designed for optimal material and work flow, and integrated manufacturing operations with separate bays for:

- 1. Three phase 66 & 132 kV Power Transformer

- 2. Single phase and Three phase 220 & 765 kV Power Transformers

- 3. Coil Winding

- 4. Insulation processing

- 5. Mild steel fabrication

- 6. Impulse Testing set-up

Automation being planned for several stages of manufacture & assembly for greater throughput Manufacturing capacity of 20,000 MVA per annum of mixed transformer ratings: Would be able to manufacture and deliver one 132 kV transformer per day.

Dust free environment

The factory environment including the interior & exterior planning ensure minimal dust inside the shop floors. Further measures like air conditioned winding shops are being created for winding of high voltage transformer windings in a sanitised area. All winding and assembly areas are further provided with epoxy flooring which further aids in reduction of ambient

Well planned material movement

The factory has been scientifically designed to ensure minimum loss of efficiency on account of movement of raw materials. Specially designed rail tracks & causeways ensure minimum time spent on movement of raw material as well as the least possible exposure to the environment

Adequate material handling facilities

With 7 cranes ranging from 5 MT to 150 MT capacity (including 2 cranes of 150 MT with the capability to work in tandem), the Sitarganj plant has capability for handling loads upto 300 MT weight. In addition air castors are being procured for easy movement of power transformers during assembly.

Fully functional material testing laboratory

In order to have a high degree of control on the inputs going into the transformers a fully functional Material testing laboratory is being set up which will have the capability to conduct all required tests on critical raw material being used in the transformers

Superior testing facilities

The testing facilities in Sitarganj are world-class. Each manufacturing area has independent test facilities with the most modern instrumentation. Computerised test benches are used reduce human intervention and provide the necessary confidence to our customers. All routine tests as per IEC 60076 and IS 2026 are done in-house. It is also possible to conduct all type tests (except Short Circuit test) as per IEC 60076/IS 2026 in-house. An Impluse generator of 1600 kVP, 160 kJ (expandable to 2400 kVP, 240 kJ) procured from Haefely, Switzerland is used to test transformers for Impulse withstand voltage.

The Highlights of the Testing facilities are-

- • Independent testing facilities for power transformers at Sitarganj plant

- • Fully automated, computerized test benches & advanced testing software for all routine tests and temperature rise tests as per international standards like IS 2026 and IEC 60076

- • In-house facilities created for ALL routine tests, Type tests such as Temperature Rise & Impulse test, and specialised tests such as FRA, Noise & Vibration measurement, etc.

- • Short circuit tests are subjected to third party testing at CPRI (India’s leading, independent test centers)

- • Impulse voltage withstand ability tests are carried out through two impulse generators (1600 kVp, 160 kJ and 900 kVp, 45 kJ) from Haefely, Switzerland with expandable capacity to test transformers of 765 kV voltage class

- • TATL’s test lab has been assessed and accredited in accordance with the standard ISO/ IEC 17025:2017 for upto 400 KV, 500 MVA by National Accreditation Board for Testing Calibration Laboratories (NABL).

- • All routine tests/Impulse test & Temperature rise tests as per international standards like IS 2026 and IEC 60076 are performed in house using fully automated, computerized test benches & advance testing software. TATL can also conduct specialized advance tests such as measurement of Partial Discharge, SFRA etc. at its works.

- • Short circuit tests are conducted at CPRI (India’s leading, independent test center)

- • Impulse voltage withstand ability tests are carried out through two impulse generators (1600 kVp, 160 Kj) from Haefely, Switzerland with expandable capacity to test transformers of 765 kV voltage class

| S. No. | Description | Installed | Proposed/Under Installation | Total |

|---|---|---|---|---|

| Installation | ||||

| 1 | 11 KV & 33 KV Transformers (T1 & T2): | |||

| a | Winding Machines for 11 KV Distribution Transformer HV & LV circular coils | 40 | - | 40 |

| b | Winding Machines for 11 KV Distribution Transformer HV & LV rectangular coils | 2 | - | 2 |

| c | Winding Machines for 33 KV Distribution Transformer HV & LV circular coils | 6 | - | 6 |

| d | Air Drying Ovens | 4 | - | 4 |

| e | Filter Machines 1.2 KL/hr and 3.0 KL/hr capacity | 2 | - | 2 |

| f | EOT Cranes - 2MT, 5MT, 25/5 MT each | 3 | - | 3 |

| g | Compressors, Vacuum Pumps, Weighing Scales, Butt Welding, Arc Welding, material handling equipment, work stations etc. | ✔ | - | ✔ |

| 2 | Insulation Cutting & Processing (T4): | |||

| a | Multi Purpose Wood working Machines | 4 | - | 4 |

| b | Wood working saws | 2 | - | 2 |

| c | Router machine | 1 | - | 1 |

| d | Air Drying Ovens | 1 | - | 1 |

| e | Scarfing, Block punching, Shearing, Sanding Machines, Compressor, Weighing Scales Material Handling equipment etc. | ✔ | - | ✔ |

| 3 | Coil Winding Area (T5): | |||

| a | Horizontal Winding Machines up to 10 MT capacity | 10 | - | 10 |

| b | Horizontal Winding Machines up to 15 MT capacity (Proposed) | 8 | - | 8 |

| c | Vertical Winding Machines (Under installation) | 1 | 1 | 2 |

| d | Formers of various sizes | ✔ | ✔ | ✔ |

| e | Air Drying Ovens | 3 | - | 3 |

| f | Pneumatic Coil Processing fixtures | 3 | - | 3 |

| g | EOT Cranes - 25/7.5 MT 150 Ton | 3 | - | 3 |

| h | Compressors, Vacuum Pumps, Weighing Scales, Butt Welding, Weighing Scales, material-handling equipment etc. | ✔ | - | ✔ |

| 4 | 66 KV & 132 KV Transformers Assembly (T6): | |||

| a | Core Cradles 3 limb upto 50 MT (Under installation) | - | 2 | 2 |

| b | Autoclave 5.3x4.0x4.5 Mtrs size with 0.3 Torr Vacuum | 1 | - | 1 |

| c | Air Drying Oven | 1 | - | 1 |

| d | Filter Machines 6 KL capacity, high vacuum | 1 | - | 1 |

| e | EOT Crane - 70/10 MT | 1 | - | 1 |

| f | Compressors, Vacuum Pumps, Weighing Scales, Brazing/ Crimping machinery, Material handling equipment, work stations etc. | ✔ | - | ✔ |

| 5 | Core Cutting Area (T7): | |||

| a | Wound Core Making machine | 1 | - | 1 |

| b | Bell Furnace for Wound Core annealing | 1 | - | 1 |

| c | CNC Slitting & Cut to length line for CRGO lamination (Proposed) | - | 1 | 1 |

| d | EOT Crane - 5 MT | 1 | - | 1 |

| e | Shearing Machines | 1 | - | 1 |

| f | Punching Machines | 1 | - | 1 |

| g | Compressor, Weighing Scales, Grinding Machine etc. | ✔ | - | ✔ |

| 6 | Fabrication Area (T8): | |||

| a | Plate Shearing machines, Brake Press, Presses, Drills, MIG welding, AC/DC Arc welding sets, Compressor, Vacuum Pump, Weighing Scales, Grinding Machines etc. | ✔ | - | ✔ |

| b | Shot blasting booth | 1 | - | 1 |

| c | Painting booth with dust free environment | - | 1 | 1 |

| d | EOT Crane - 25/5 MT | 1 | - | 1 |

| 7 | 220 KV to 765 KV Transformers Assembly (T9): | |||

| a | Core Cradles 5 limb upto 150 MT (Proposed) | - | 1 | 1 |

| b | Vapour Phase Drying 11.5x6.0x5.5 Mtrs size | 1 | 1 | 2 |

| c | Filter Machines 12 KL capacity, high vacuum | 1 | - | 1 |

| d | Air castor unit for movement of transformers (Proposed) | - | 1 | 1 |

| e | EOT Cranes - 150/25 MT with beam for tandem lifting (total 300 MT) | 2 | - | 2 |

| f | Compressors, Vacuum Pumps, Weighing Scales, Drill, Grinding Machines, material handling equipment, work stations etc. | ✔ | - | ✔ |

| 8 | Common Facilities: | |||

| a | Raw Transformer Oil Storage Tanks 90 KL capacity each | 2 | - | 2 |

| b | Processed Transformer Oil Storage tanks (Total capacity 144 KL) | 5 | - | 5 |

| c | Thermic Oil heating system, 1.6 Mn K. Cal capacity | 1 | - | 1 |

| d | Diesel Generating Sets | 2 | - | 2 |

| e | Power S/S and distribution facility | ✔ | - | ✔ |

| 9 | Testing Equipment: | |||

| a | Distribution Transformers (11 KV - T1) All test equipments for conducting all routine tests and Temperature rise test. Meters and CT/PT with 0.5 % accuracy and Yokogawa make power analyzer for loss measurement. | ✔ | - | ✔ |

| b | Distribution Transformers (33 KV - T2)All test equipments for conducting all routine tests and Temperature rise test. Meters and CT/PT with 0.2 % accuracy and Yokogawa make power analyzer for loss measurement. All test readings transferred thru RS 232 Port for direct print out of test results | ✔ | - | ✔ |

| c | Medium Power Transformers (66 KV & 132 KV - T6) All test equipments for conducting all routine tests and Temperature rise test. Meters and CT/PT with 0.2 % accuracy and Yokogawa make power analyzer for loss measurement. All test readings transferred thru RS 232 port for direct print out of test results. 300 KV Potential divider, Sphere gaps, SFRA equipment, etc. | ✔ | - | ✔ |

| d | Large Power Transformers (220KV to 765 KV - T9) All test equipments for conducting all routine tests and Temperature rise test - best International makes. Meters and CT/PT with 0.1 % accuracy and Yokogawa make power analyzer for loss measurement. All test readings transferred thru RS 232 Port for direct print out of test results. 800 KV Potential divider, Sphere gaps, Partial discharge measurement, SFRA equipment, 3 Phase MG Sets (50 Hz – 180 Hz), 2x4 MVAr Reactor, Testing Transformers, Noise Level Meter, Non contact temperature measuring gun, Corona Shields, etc. | - | ✔ | ✔ |

| e | Common Facility (T9) Impulse Generator 1600 KVp, 160 Kj with RSG, extendable to 2400 KVp, 240 KJ | ✔ | - | ✔ |